Casting film processing technology

- Categories:Trade News

- Author:

- Origin:

- Time of issue:2021-09-10

- Views:0

(Summary description)Cast film is a non tensile and non directional flat extruded film produced by melt salivation quenching.

Casting film processing technology

(Summary description)Cast film is a non tensile and non directional flat extruded film produced by melt salivation quenching.

- Categories:Trade News

- Author:

- Origin:

- Time of issue:2021-09-10

- Views:0

■ Product introduction

definition

Cast film is a non tensile and non directional flat extruded film produced by melt salivation quenching.

type

Solvent casting film and extrusion melt casting film.

Solvent cast film: due to the need to use a large number of organic solvents, heating and volatilizing to remove and recover solvents requires a lot of energy, and the operation cost and equipment cost are also large, so it is less used in actual production.

Extrusion melt casting film: there are two ways: single-layer salivation and multi-layer coextrusion salivation. Single layer film requires good low temperature heat sealing performance and flexibility. Multilayer coextrusion casting film can generally be divided into three layers: heat seal layer, support layer and corona layer. The selection of materials is wider than that of single-layer film. Materials meeting the requirements of each layer can be selected separately to endow the film with different functions and uses.

characteristic

Compared with film blowing, it is characterized by fast production speed, high output, and excellent transparency, gloss and thickness uniformity of the film.

#2

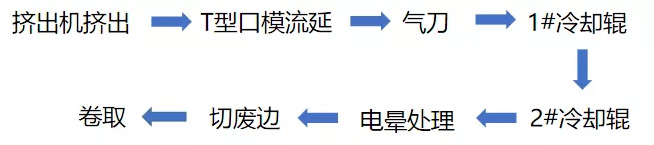

■ Production process

One of the processing methods of extrusion melt casting film:Extrusion melt casting

Production process flow:

#3

■ Cast film raw material

Resin for extruded cast film:

PP、PE、PA

PS、PETIt is mainly used for biaxial tensile film and used in tape casting film;

EVOH (ethylene vinyl alcohol copolymer) and PVDC (polyvinylidene chloride) which have good barrier effect on the transmission of oxygen and water vapor are commonly used in multilayer co extruded cast films.

#4

■ Characteristics of extrusion melt casting films

Fast production speed; In the extrusion casting process, the temperature of the cooling roller can be 0 ~ - 5 ℃, which is directly close to the roller, and the cooling effect is good.

Good transparency. Both PP and PE can produce films with good transparency by extrusion casting.

The film thickness uniformity of extrusion casting method is good.

The longitudinal and transverse properties of extrusion casting film are balanced. In principle, the film produced by extrusion casting method flows from one roller to another, and there should be no tension of coiling or traction. Therefore, the extruded casting film is not stretched longitudinally and transversely, and its performance is uniform.

Just because the extruded cast film is not stretched in any direction, its heat sealing performance is better than that of the blown film, while the biaxially stretched film has no heat sealing performance. The shrinkage of extruded casting film when heated is very small, which is conducive to heat sealing and bag making.

#5

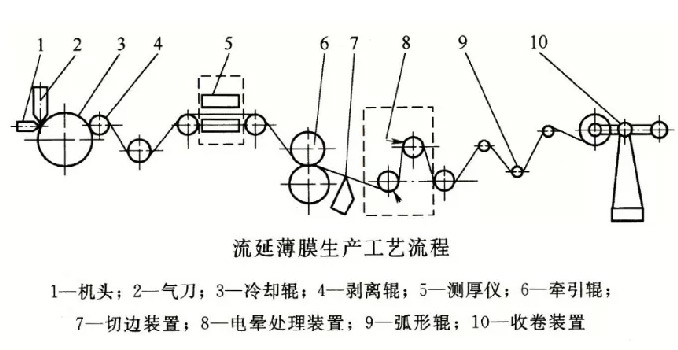

■ Casting film forming equipment

Typical forming equipment for cast film includes & ldquo; Extruder, head, cooling device, thickness measuring device, trimming device, corona treatment device, winding device & rdquo; Wait.

Extruder

Screw diameter:Φ90~ Φ200

Aspect ratio:25~33

The extruder head must be mounted on a moving base

nose

Branch head

Hanger head

Distribution screw head

Other forms of handpiece

Molten material filtering device

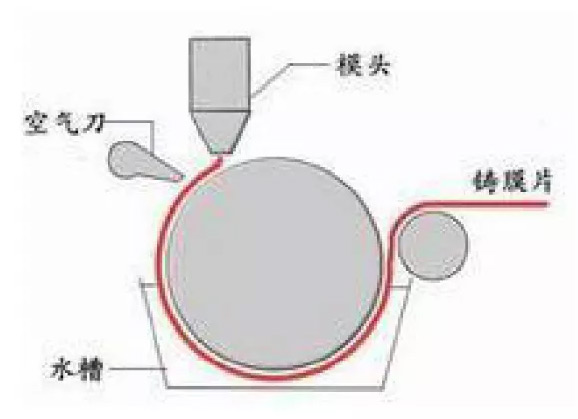

cooling system

1)Cooling roller

Double roll water tank cooling

Single roll water tank cooling

2)Air knife

Thickness measuring device

Most side rear devices adopt & beta; The detector moves back and forth along the transverse direction to measure the film thickness and display it on the fluorescent screen.

Trimming device

Extruded film due to & ldquo; Thin neck & rdquo; Phenomenon, which will make the edge of the film thicker. The edge of the film needs to be cut off to ensure that the end of the film roll is neat and the surface is flat.

corona treatment

Corona treatment is a kind of electric shock treatment, which makes the surface of the substrate more adhesive.

Coiling device

The film adopts the form of active winding, generally automatic or semi-automatic cutting and roll changing.

The film winding device also includes a film cutting device.

The cutting methods of film include electrothermal cutting method and blade cutting method.

#6

■ Application and development trend of cast film

application

1.Multilayer coextrusion casting film

It is mainly used for high-grade films that need to be compounded and specialized in the packaging industry. The product range includes low-temperature heat sealing film, aluminized substrate film and high barrier film.

Film, cooking film, extinction film, antistatic film, antibacterial film, PVB explosion-proof film, etc.

2.Multilayer composite film

Food, beverage, tea, meat products, agricultural products, seafood, textiles, chemical products, sanitation.

Packaging of health products, medical supplies, cultural and educational supplies, cosmetics, etc.

Four development trends of cast film

1.Material reduction———In order to meet the requirements of packaging reduction and environmental protection, packaging materials are thin and lightweight

2.Use security———Pay attention to human health, and materials should be safe

3.Product intelligence———It has many functions, such as fresh-keeping, anti-corrosion, antibacterial, anti-counterfeiting, prolonging shelf life and so on

Scan the QR code to read on your phone

Recommended products

Xiamen Jufu plastic products Co., Ltd.

Service hotline:

Add: No. 28, Xinglin North 2nd Road, Jimei District, Xiamen City, Fujian Province

Website: www.chinajufu.com

E-mail: erinzhang@chinajufu.com

+86-592-6241802

+86-592-6241802

Feedback

Feedback